Life is developing more and more, human labor is gradually being replaced by machines. That helps increase productivity, efficiency and accuracy in work. That’s why the robotic arm was born. This is certainly not a strange term for everyone.

1. What is a Robot Arm?

One of the applications of robots in the manufacturing industry is robotic arms. Just like the human arm, it performs operations with the product. But it can reach higher accuracy and faster than humans. Therefore, this product is increasingly widely used in large factories around the world in general and Vietnam in particular. Can perform tasks such as picking, lifting, lowering, manipulating the product. In particular, it is possible to program specific actions depending on the purpose of human use.

2. Robot arm classification

- Cylindrical robot: whose axis forms a cylindrical coordinate system. Applied in assembly technology, spot welding, processing machine tools, diecasting machines.

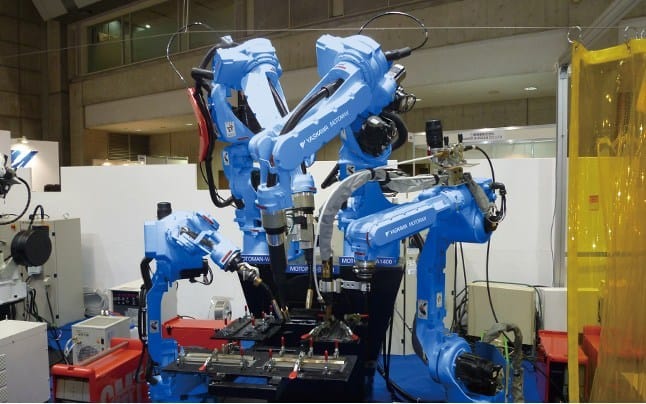

- Articulated Robots: Robots with at least three rotating joints. It is possible to perform manipulations with small parts with high precision. Used in many jobs such as assembling parts, cutting, welding, polishing, …

- Parallel Robot: Its joints are prismatic or rotary joints.

- Gantry robot: This joint is a prismatic joint. Used for electronic component assembly, welding, cutting and processing of machine tools.

- Spherical robot: Axis motion forms a polar coordinate system. Used for gas welding, arc welding, spot welding, processing machine tools, diecasting, machine fettling, etc.

- SCARA robot: There are rotary joints which are parallel rotating joints. Operates on a flat surface, used in assembly and processing of machine parts.

3. Application in production

3.1 In the technology of manufacturing electronic components

- With the manipulation of small details such as on electronic components, it is very suitable to use this product. It performs with incredibly high precision and consistency. When assembling electronic components, the disadvantages of using traditional methods are completely eliminated. The solder joints are precise, the aesthetics are also higher and the product is more uniform.

- When using human resources, moving product in the chain has the potential to break at weld joints. The production is also affected by many factors on the health and mood of workers. The products made are not consistent. Want to increase the number of products while human resources cannot meet. So this selection is a great choice.

- Using robotic arms in production not only increases labor productivity but also increases the quality of output products. Minimizing defective, damaged products, saving resources. Especially in the electronic component manufacturing industry that requires high precision.

3.2 In food production

Nowadays, people’s demand for food is increasing day by day. Therefore, the production of food and beverage also increased. In this era of industrial development, many factories have put into use in their production lines.

- In food and beverage production, the robotic arm acts as a worker for packaging, labeling, capping, etc.

- It also acts as an “inspector” to identify defective, damaged, dented, distorted, and unqualified products. Not only that, it also has the ability to quantify the excess of the product to supplement, or reduce.

3.3 In the transportation of goods

As everyone knows, transporting and arranging goods is an indispensable step in production. This job requires health and endurance.

- Saving labor.

- It is possible to improve the shortcomings of traditional human-powered loading and unloading.

- When using human labor can be affected by many other external factors, but not when applying technology.

- Goods are neatly loaded and unloaded according to the available programming program.

- Loading and unloading heavy goods for a long time.

The advantages that robots bring in the manufacturing industry are immense. If you are someone who is looking to develop your factory, do not hesitate, call our Hotline 0945.200.793. Sumitech is one of the leading companies in machinery in the industry. A team of highly qualified engineers specializes in consulting, designing and installing robotic arm systems. We hope to provide a solution that contributes to the improvement and development of your production system.