Calculating the factory’s electrical conductors helps businesses control the construction progress as well as the cost of purchasing their own materials. See the calculation method and the most detailed calculation notes in the article below.

1. Criteria for calculating the most standard factory electrical conductors

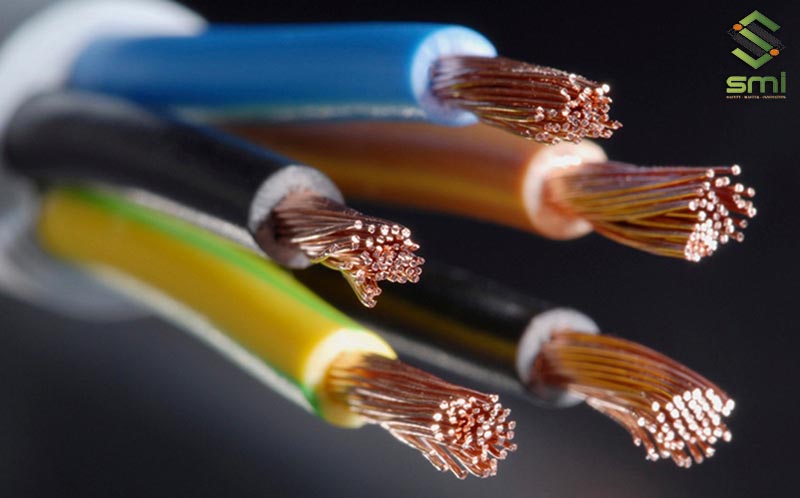

Electrical conductors play a very important role, used to transmit power to parts and equipment in the factory. Not only that, the electrical conductor also has an insulating function to ensure safety for people and equipment during use. Therefore, calculating and selecting electrical conductors is an extremely important job, having a direct impact on production efficiency and safety of factory workers.

To calculate and select the most suitable type of electrical conductor for the workshop, engineers need to rely on the loss parameters on the wire and the carrying capacity of the conductor. The above two parameters are determined by the following three factors:

- Material of electrical conductor: Normally, the conductor is made of aluminum or copper with PVC sheath. An electrical conductor with good materials will ensure a long life, helping to optimize the time and cost of using the business.

- Length of conductor: Make sure to fully equip, avoid shortage/excess of conductors. Prepare all necessary wires to help ensure the construction progress and costs of the business.

- Cross-section of conductors: Be sure to be large enough to be able to transmit power to each part, equipment and machinery in the factory. Avoid overloading causing unsafety to people and property of the business.

At the factory, due to the characteristics of the location of the machines and equipment, the length of the conductor and the type of conductor used usually do not change too much. In order to ensure efficient operation of the electrical system, to limit the need to replace wires of inappropriate length, electrical engineers need to choose the right type of wire with the right material and length and calculate the conductor cross-section. reasonable factory electricity.

See more: Details of 5 steps to design the factory electrical system STANDARD – BEAUTIFUL

2. How to calculate the cross-section of the factory’s electrical conductors

First, to calculate the cross-section of electrical conductors in the workshop, engineers calculate the total capacity of electrical equipment at the factory when they are operating at the highest level. Then calculate the amperage and finally the conductor cross-section. The calculation formulas are as follows:

Calculate the current capacity P:

P = P1 + P2 + P3 +…+ Pn + Px

In there:

- P is the total operating capacity of the factory (W);

- P1, P2, P3,… Pn is the capacity of the equipment used in the factory (W);

- Px is the expected future power (W).

Calculate the amperage l:

|

Type 220V 1Phase |

Type 380V 3Phase |

| I=P/(U * Cos (Phi)) | I=P/(căn bậc 2 của 3 * U * Cos(Phi)) |

In there:

- I is the amperage (A);

- P is the total operating capacity of the factory (W);

- U is the potential difference (V).

Calculate the cross-section of the factory electrical conductors according to the economical J current method:

Fktij = Iij / Jkt

In there:

- F is the required conductor cross-section (mm2);

- I is the amperage (A);

- J is the allowable current density (A/mm2):

- Allowable current density for copper wire Jđ = 6 A/mm2

- Allowable current density for aluminum wire Jn = 4.5 A/mm2

From F ktij look up the table to find the nearest standard wire cross section.

Check the selected factory electrical conductor cross-section according to the technical standards:

△Umaxbt ≤ △Ubtcp

△Umaxsc ≤ △Usccp

Isc ≤ Icp

With cables it is necessary to check the thermal stability of the short-circuit current of the cross-section:

In there:

- α is the coefficient of heat (for copper cable α = 6, aluminum cable α = 11);

- tqd is the conversion time (with average and low voltage grid taken as short circuit breaking time).

In addition, in case you already have parameters of wire cross-section (S), current density (J) and want to rely on that to choose a suitable conductor material, you can refer to the following table:

| Wire Type | Economical current density (A/mm2) | ||

| Hours of maximum load usage in a year (h) | |||

| ≤3000 | 3000 ÷ 5000 | ≥5000 | |

| Copper | 2,5 | 2,1 | 1,8 |

| Wire A and AC | 1,3 | 1,1 | 1 |

| Copper Cable | 3,5 | 3,1 | 2,7 |

| Aluminum Cable | 1,6 | 1,4 | 1,2 |

Note that, when choosing factory electrical conductors, should choose to buy conductors with a cross-sectional area one level larger than the calculated data to ensure electrical safety. Not only that, businesses can also feel more secure if the factory generates new electrical equipment in the future.

Besides calculating the factory wiring yourself, you can refer to the wiring chart below:

| Cadivi (mm) | Taya (mm) | Power (kW) | Power (kW) | Amperage (A) |

| Tại 380V | Tại 220V | 220V | ||

| 0,75 | 0,75 | 1,05 | 0,35 | 1,875 |

| 1 | 1 | 1,40 | 0,47 | 2,5 |

| – | 1,25 | 1,75 | 0,58 | 3,125 |

| 1,5 | 1,5 | 2,10 | 0,70 | 3,75 |

| 2 | 2 | 2,81 | 0,94 | 5 |

| 2,5 | 2,5 | 3,51 | 1,17 | 6,25 |

| 3,5 | 3,5 | 4,91 | 1,64 | 8,75 |

| 4 | 4 | 5,61 | 1,87 | 10 |

| 5,5 | 5,5 | 7,71 | 2,57 | 13,75 |

| 6 | 6 | 8,42 | 2,81 | 15 |

| 8 | 8 | 11,22 | 3,74 | 20 |

| 10 | 10 | 14,03 | 4,68 | 25 |

| – | 11 | 15,43 | 5,14 | 27,5 |

| – | 14 | 19,64 | 6,55 | 35 |

| 16 | 16 | 22,44 | 7,48 | 40 |

| – | 22 | 30,86 | 10,29 | 55 |

| 25 | 25 | 35,06 | 11,69 | 62,5 |

| – | 30 | 42,08 | 14,03 | 75 |

| 35 | 35 | 49,09 | 16,36 | 87,5 |

| – | 38 | 53,30 | 17,77 | 95 |

| 50 | 50 | 70,13 | 23,38 | 125 |

| – | 60 | 84,15 | 28,05 | 150 |

| 70 | 70 | 98,18 | 32,73 | 175 |

| – | 80 | 112,20 | 37,40 | 200 |

| 95 | 95 | 133,24 | 44,41 | 237,5 |

| – | 100 | 140,25 | 46,75 | 250 |

| 120 | 120 | 168,30 | 56,10 | 300 |

| – | 125 | 175,31 | 58,44 | 312,5 |

| 150 | 150 | 210,38 | 70,13 | 375 |

| – | 150 | 210,38 | 70,13 | 375 |

| 185 | 185 | 259,46 | 86,49 | 462,5 |

| – | 200 | 280,50 | 93,50 | 500 |

| 240 | 240 | 336,60 | 112,20 | 600 |

| – | 250 | 350,63 | 116,88 | 625 |

| 300 | 300 | 420,75 | 140,25 | 750 |

| 400 | – | 561,00 | 187,00 | 1000 |

3. Some notes when calculating factory electrical wiring

Each different factory will have different load capacity. Therefore, the calculation of the cross-section and the selection of the type of conductor for each factory is also different. Please note the following issues:

Choose the correct conductor cross-section:

If the wiring has a small cross-section, the power transmission line of the system will be overloaded, causing the aptomat to collapse, reducing the life of the conductor. Not only that, operations and product production were also interrupted. More dangerously, it will cause heat to damage the insulation layer, cause a fire, lose electrical safety, and endanger people and property of the business.

If the wiring is too large for the factory, it will cause excess capacity and waste assets.

Origin of conductor:

When choosing, please check the following factors: date of manufacture, origin, wire type, wire cross-section, etc. to avoid buying products of unknown origin, poor quality and not able to withstand electrical capacity. in the factory caused an explosion.

Some tips to help you choose electrical conductors:

- The stretchable insulation is as long as possible;

- Carry out twisting and folding of the way several times to test the durability;

- Good conductors are usually shiny, twisted, folded, and broken without breaking.

See more: Step-by-step instructions for a STANDARD factory electrical diagram

4. SUMITECH – The leading unit in consulting, designing and constructing factory electrical systems

With more than 10 years of experience in building industrial electrical systems for factories, SUMITECH confidently asserts itself as one of the prestigious and quality units. SUMITECH always focuses on equipping modern facilities and training a team of professional engineers. Currently, we have nearly 30 engineers who have many years of M&E construction, graduated with master’s and university degrees.

With such a system of high-quality machinery and human resources, SUMITECH confidently supports customers to calculate the correct factory electrical wiring, ensuring the efficiency of the factory’s electrical system and the safety of its assets and employees. customer business.

Please contact SUMITECH for advice on calculating the most accurate and suitable factory wiring:

- Hotline: 0989.060.987

- Website: sumitech.vn

- Fanpage: https://www.facebook.com/sumitech.industrial.jsc/

- Email: info.sumitechvn@gmail.com